Product Features

· Good dimensional stability, good demolding properties, temperature resistance up to 250℃ or higher

· No low molecular weight is released during the crosslinking process of the mold silicone, so the volume remains unchanged, and the linear shrinkage rate is less than 0.1%.

· No limitation on the thickness of the product, can be deeply cured.

· High tensile and tear strength, with anti-reversion properties at high temperatures of 200℃.

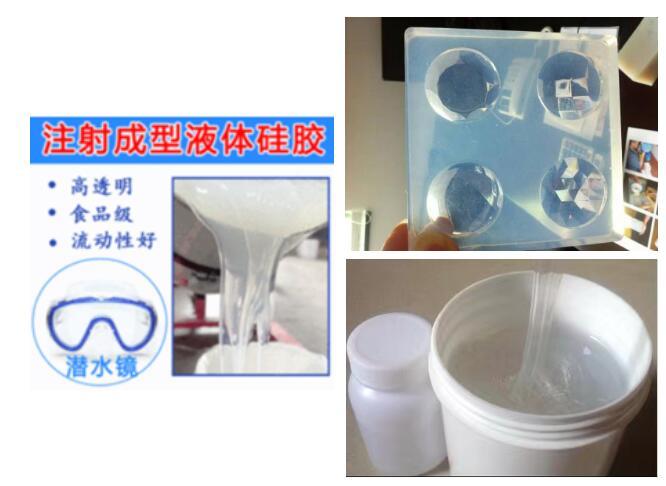

Product Applications

Injection-type mold silicone is professionally used for rapid prototyping of imitation gemstones, imitation zircon, imitation crystal faceted diamonds, resin drills, etc.; commonly used for molding to cast epoxy resin, polyester resin, polystyrene, vinyl plastics, paraffin, low melting point alloys, concrete, etc., for the replication of cultural relics and fine arts crafts.

Product Parameter Table

Model | JH-2135 | JH-2235 |

Appearance | Transparent | Transparent |

Hardness (Shore Aº) | 35±2 | 35±2 |

Mixing weight ratio of two components (A:B) | 10:1 or 1:1 | 10:1 or 1:1 |

Dynamic viscosity (mPa.s) | 120000±5000 | 120000±5000 |

Tensile strength (MPa) | 4.8 | 5.2 |

Tear strength (kN/m) | 18±2 | 20±2 |

Elongation (%) | 560 | 680 |

Working time (min) | 30-40 | 30-40 |

Curing time (h) | 4-6 | 4-6 |

Linear shrinkage rate (%) | ≤0.1 | ≤0.1 |

Product Image

Packaging Specifications:

Component A is 20KG/barrel, 25KG/barrel, 200KG/barrel.

Keywords

Injection

Contact Us

Classification