Product Features

· Food grade, non-toxic and tasteless, FDA food grade certified

· High tensile and tear strength, multiple mold releases, not easy to deform

· Good fluidity, easy to pour, can cure at room temperature or with heat, convenient to operate

· Not limited by the thickness of the product, can be deeply vulcanized

· Low linear shrinkage rate (≤0.1%), no low molecular weight released during crosslinking, thus the volume remains unchanged, high accuracy of replicated products

· Excellent chemical corrosion resistance, high temperature resistance can reach 250℃

Product Applications

· Manufacturing of precision molds for metal crafts, alloy vehicles, etc.

· Molding of materials such as epoxy resin, polyester resin, polystyrene, vinyl plastics, paraffin, etc.

· Mold manufacturing for large cement components, cultural stones, concrete products, etc.

· Design and production of high-precision prototype models, automotive development, power fan blade design and development, military industry development

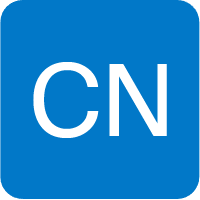

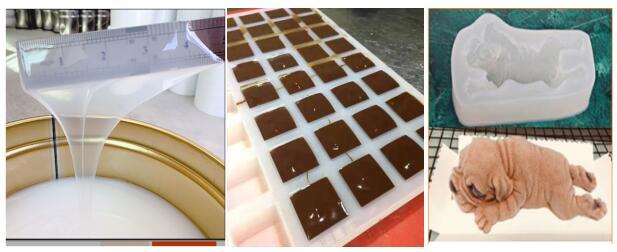

· Food grade mold production

· Can also be specially formulated according to customer product requirements

Product Parameter Table

H series addition-type translucent mold silicone parameters (25℃)

Model | H615 | H620 | H625 | H630 | H640 | H650 | H660 |

Appearance | Translucent | Translucent | Translucent | Translucent | Translucent | Translucent | Off-white |

Hardness (Shore Aº) | 15±2 | 20±2 | 25±2 | 30±2 | 40±2 | 50±2 | 60±2 |

Two-component mixing weight ratio (A:B) | 1:1 | 1:1 | 1:1 | 1:1 | 1:1 | 1:1 | 1:1 |

Dynamic viscosity (mPa.s) | 4000±2000 | 5000±2000 | 6000±2000 | 7000±2000 | 8000±2000 | 9000±2000 | 10000±2000 |

Tensile strength (MPa) | 4.6 | 5.6 | 6.2 | 6.2 | 6.8 | 4.3 | 4.2 |

Tear strength (kN/m) | 18±2 | 25±2 | 25±2 | 25±2 | 27±2 | 15±2 | 12±2 |

Elongation (%) | 530 | 560 | 600 | 600 | 680 | 270 | 190 |

Density (g/cm) | 1.05 | 1.05 | 1.07 | 1.13 | 1.14 | 1.16 | 1.18 |

Operation time (min) | 30-60 | 30-60 | 30-60 | 30-60 | 30-60 | 30-60 | 30-60 |

Vulcanization time (h) | 4-6 | 4-6 | 4-6 | 4-6 | 4-6 | 4-6 | 4-6 |

Linear shrinkage rate (%) | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 |

T series addition-type translucent mold silicone parameters (25℃)

Model | T615 | T620 | T625 | T630 | T640 | T650 | T660 |

Appearance | Transparent | Transparent | Transparent | Transparent | Transparent | Transparent | Off-white |

Hardness (Shore Aº) | 15±2 | 20±2 | 25±2 | 30±2 | 40±2 | 50±2 | 60±2 |

Two-component mixing weight ratio (A:B) | 1:1 | 1:1 | 1:1 | 1:1 |

Precautions

· The silicone should be stored sealed, and the mixed silicone should be used up at once within the specified time to avoid waste.

· Do not let the silicone come into contact with nitrogen (N), sulfur (S), phosphorus (P), tin (Sn), lead (Pb), mercury (Hg), alcohols, water, etc., such as organotin compounds and silicone rubber containing organotin, sulfur, sulfur compounds, and sulfur-containing rubber, amine compounds and materials containing amines, nor should it come into contact with containers or molds that have been treated with condensation-type silicone, otherwise, the addition-type liquid silicone may become sticky, cure incompletely, or even not cure at all.

Product Images

Packaging Specifications:

1. A and B materials in a 1:1 ratio, regular packaging

40KG/set (A component 20KG + B component 20KG)

50KG/set (A component 25KG + B component 25KG)

400KG/set (A component 200KG + B component 200KG)

2. A and B materials in a 10:1 ratio, regular packaging

22KG/set (A component 20KG + B component 2KG)

220KG/set (A component 200KG + B component 20KG)

Keywords

Mold

Contact Us

Classification