Product Parameter Table

H series addition-type translucent mold silicone parameters (25℃)

Model | H615 | H620 | H625 | H630 | H640 | H650 | H660 |

Appearance | Translucent | Translucent | Translucent | Translucent | Translucent | Translucent | Off-white |

Hardness (Shore Aº) | 15±2 | 20±2 | 25±2 | 30±2 | 40±2 | 50±2 | 60±2 |

Two-component mixing weight ratio (A:B) | 1:1 | 1:1 | 1:1 | 1:1 | 1:1 | 1:1 | 1:1 |

Dynamic viscosity (mPa.s) | 4000±2000 | 5000±2000 | 6000±2000 | 7000±2000 | 8000±2000 | 9000±2000 | 10000±2000 |

Tensile strength (MPa) | 4.6 | 5.6 | 6.2 | 6.2 | 6.8 | 4.3 | 4.2 |

Tear strength (kN/m) | 18±2 | 25±2 | 25±2 | 25±2 | 27±2 | 15±2 | 12±2 |

Elongation (%) | 530 | 560 | 600 | 600 | 680 | 270 | 190 |

Density (g/cm) | 1.05 | 1.05 | 1.07 | 1.13 | 1.14 | 1.16 | 1.18 |

Operation time (min) | 30-60 | 30-60 | 30-60 | 30-60 | 30-60 | 30-60 | 30-60 |

Vulcanization time (h) | 4-6 | 4-6 | 4-6 | 4-6 | 4-6 | 4-6 | 4-6 |

Linear shrinkage rate (%) | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.1 |

T series addition-type translucent mold silicone parameters (25℃)

Model | T615 | T620 | T625 | T630 | T640 | T650 | T660 |

Appearance | Transparent | Transparent | Transparent | Transparent | Transparent | Transparent | Off-white |

Hardness (Shore Aº) | 15±2 | 20±2 | 25±2 | 30±2 | 40±2 | 50±2 | 60±2 |

Two-component mixing weight ratio (A:B) | 1:1 | 1:1 | 1:1 | 1:1 |

Precautions

· The silicone should be stored sealed, and the mixed silicone should be used up at once within the specified time to avoid waste.

· Do not let the silicone come into contact with nitrogen (N), sulfur (S), phosphorus (P), tin (Sn), lead (Pb), mercury (Hg), alcohols, water, etc., such as organotin compounds and silicone rubber containing organotin, sulfur, sulfur compounds, and sulfur-containing rubber, amine compounds and materials containing amines, nor should it come into contact with containers or molds that have been treated with condensation-type silicone, otherwise, the addition-type liquid silicone may become sticky, cure incompletely, or even not cure at all.

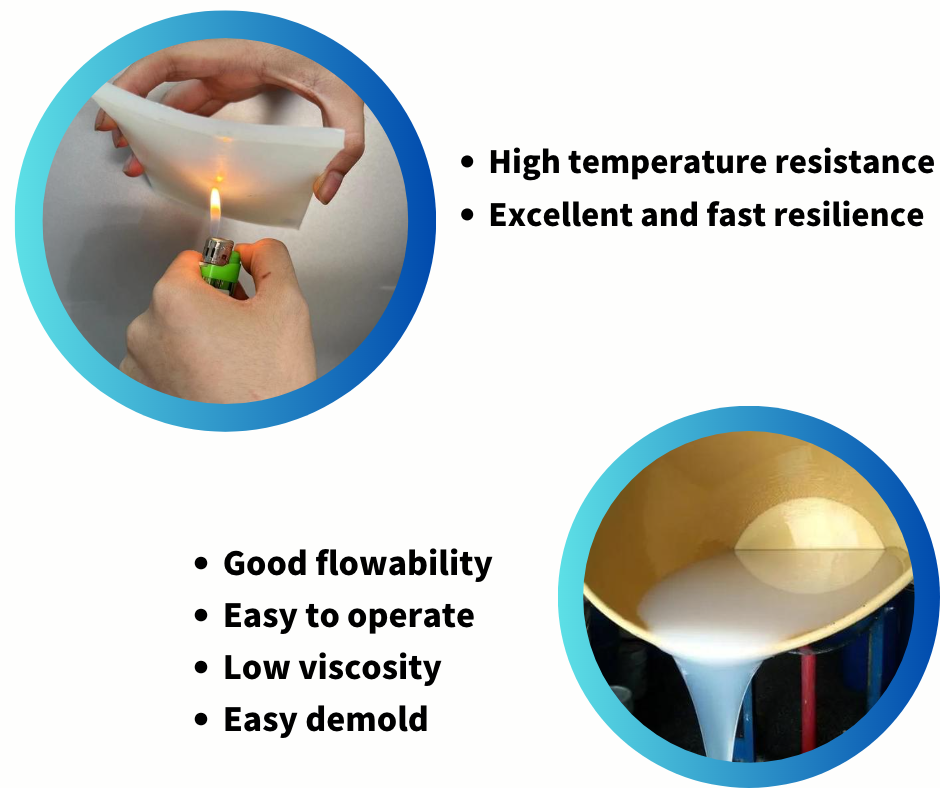

Product Images

Packaging Specifications:

1. A and B materials in a 1:1 ratio, regular packaging

40KG/set (A component 20KG + B component 20KG)

50KG/set (A component 25KG + B component 25KG)

400KG/set (A component 200KG + B component 200KG)

2. A and B materials in a 10:1 ratio, regular packaging

22KG/set (A component 20KG + B component 2KG)

220KG/set (A component 200KG + B component 20KG)

Keywords

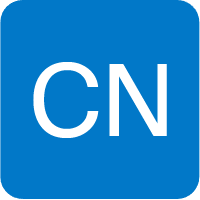

Food grade silicone for Mold making

Contact Us

Classification