Product Features

· Low viscosity, good fluidity, easy to demold products

· Non-shrinkable, wear-resistant, multiple printing times

· No oil penetration, no deformation, good resistance to ink solvents

· High tensile and tear strength, low linear shrinkage rate

· Good ink transferability, easy to apply oil, and clear patterns in printing

· Good resilience

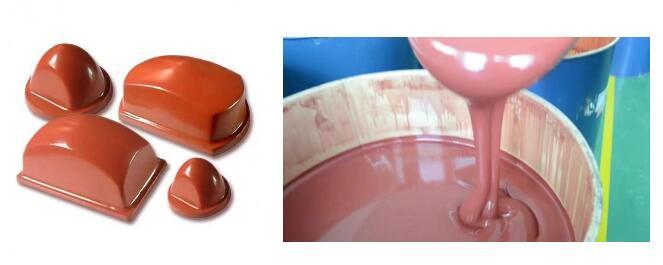

Product Applications

Transfer printing silicone is a liquid silicone used to make transfer printing pads, mainly applied in plastic toys, PVC toys, craft gifts stationery, electronic products, lighting, electroplated goods, electronic toys, trademarks, ceramic printing, and printing of irregular patterns, etc.

Transfer Printing Silicone Operation

1. First, clean the mold with detergent, then wipe or blow dry the moisture in the mold, and apply a layer of release agent.

2. The normal ratio of transfer printing silicone to silicone oil is determined according to customer requirements. If the customer requires a large printing area and needs a soft pad, then increase the silicone oil. Conversely, if a harder pad is needed, do not add or add less silicone oil. Generally, the hardness of the transfer printing pad should be suitable between 15A°-25A°. If the amount of silicone oil added is too large, the pad will be too soft, and the number of prints will be limited. Even the best quality silicone will have its molecular weight damaged by silicone oil, resulting in wear resistance, solvent resistance, and aging issues.

3. The normal ratio is as follows: 100 grams of silicone with 30 grams of silicone oil, pad hardness 15A°, suitable for transfer printing on alloy toy cars and small patterns with a relatively small contact area. If a larger pressure contact area is required, a soft pad is needed. The ratio of silicone to silicone oil can be 100:30 or 100:50, but it should be noted that the larger the amount of silicone oil added, the softer the pad will be, which will reduce the number of prints, wear resistance, and solvent resistance, leading to an increase in costs and waste of raw materials.

4. The amount of curing agent added and the chemical reaction of silicone are as follows: take 100 grams of silicone, add 50 grams of silicone oil, and then mix and stir. After the silicone oil and silicone are fully mixed evenly, add 2%-3% of the total weight of silicone and silicone oil as curing agent, and stir for 2-3 minutes before vacuuming. The vacuuming time generally should not exceed 10 minutes; if the vacuuming time is too long, the gel will cure quickly, affecting the quality of the pouring.

Product Parameter Table

| Model |

H912 |

H916 |

H966 |

| Appearance |

White |

White |

White |

| Hardness (Shore Aº) |

25±2 |

16±2 |

20±2 |

| Two-component mixing weight ratio (A:B) |

100:2/3 |

100:2/3 |

10:1 |

| Dynamic viscosity (mPa.s) |

25000±2000 |

57000±2000 |

26000±2000 |

| Tensile strength (MPa) |

4.2 |

5.2 |

4.5 |

| Tear strength (kN/m) |

12±2 |

16±2 |

20±2 |

| Elongation (%) |

560 |

680 |

580 |

| Operation time (min) |

30-40 |

30-40 |

30-40 |

| Curing time (h) |

4-6 |

4-6 |

4-6 |

| Linear shrinkage rate (%) |

≤0.2 |

≤0.2 |

≤0.2 |

Product Image

Packaging Specifications:

Component A is available in 20KG/barrel, 25KG/barrel, 200KG/barrel.

Keywords

Transfer printing

Contact Us

Classification