The application scenarios and advantages of foam silicone.

Nov 29,2024

Applications and Advantages of Foam Silicone

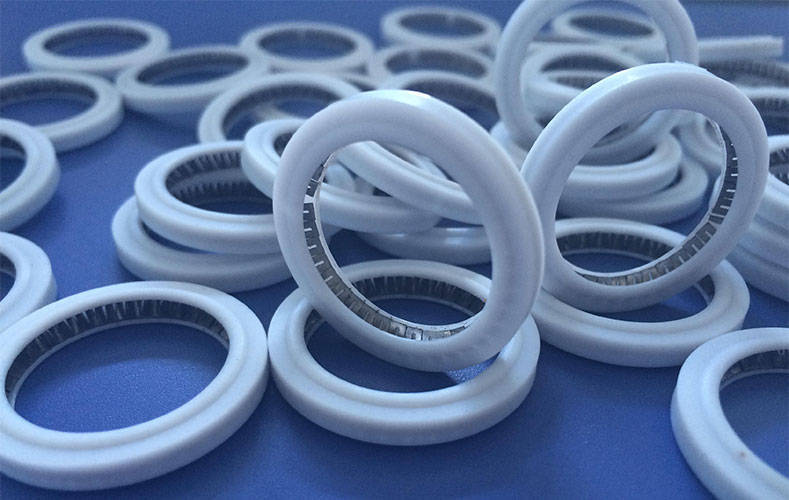

In today's era of diversified material applications, foam silicone, as a high-performance and multifunctional material, is gradually showcasing its unique charm across various industries. With its excellent physical properties, chemical stability, and environmental friendliness, foam silicone stands out in numerous application scenarios, becoming one of the indispensable materials. This article will start from the basic concept of foam silicone and delve into its diverse application scenarios and inherent advantages.

I. Basic Concept of Foam Silicone

Foam silicone, as the name suggests, is a material that introduces bubbles into silicone through physical or chemical methods, forming a porous structure. This porous structure endows foam silicone with a series of excellent properties such as lightweight, high elasticity, sound insulation, thermal insulation, shock absorption, and waterproofing. Depending on the foaming process, foam silicone can be divided into closed-cell foam silicone and open-cell foam silicone. The former has independent and sealed bubbles, while the latter has interconnected bubbles, and the different structural characteristics determine their application differences.

II. Application Scenarios of Foam Silicone

1. Electronics and Electrical Industry

In the electronics and electrical field, foam silicone is widely used in sealing, shock absorption, and thermal protection of electronic products due to its good insulation, high-temperature resistance, and flame retardancy. For example, battery pads, speaker pads, and camera shock pads in mobile devices such as smartphones and tablets all use foam silicone materials, effectively enhancing product durability and user experience.

2. Automotive Industry

The automotive industry is another important application field for foam silicone. In vehicle manufacturing, foam silicone is used as thermal insulation material for the engine compartment, sound insulation pads for car doors, and seat fillers, which not only reduces vehicle weight and improves fuel efficiency but also significantly enhances vehicle comfort and safety. Additionally, its oil resistance and aging resistance make foam silicone an ideal choice for automotive seals and pipeline protection.

3. Construction and Home

In the construction and home field, foam silicone is often used in waterproofing layers for roofs, sound insulation boards for walls, and waterproof mats for bathrooms due to its excellent waterproof, moisture-proof, and sound insulation properties. At the same time, its environmentally friendly, non-toxic, and easy-to-process characteristics also make it an ideal soundproofing and thermal insulation material in home decoration, such as soundproof curtains and thermal insulation floor mats, creating a more comfortable and healthy living environment for people.

4. Medical and Health

The medical and health field has very high requirements for the safety and biocompatibility of materials. Foam silicone, with its non-toxic, odorless, antibacterial, and easy-to-clean characteristics, has become an ideal material for medical devices, rehabilitation equipment, and personal hygiene products. For example, medical mattresses, wheelchair cushions, and baby bottle nipples widely use foam silicone, providing patients and consumers with a safer and more comfortable experience.

III. Advantages of Foam Silicone

1. Excellent Physical Properties

Foam silicone has excellent elasticity, toughness, and tear resistance, able to withstand significant deformation without breaking, ensuring product durability and stability. At the same time, its lightweight characteristics make products more convenient during transportation and installation.

2. Good Environmental Adaptability

Foam silicone can maintain stable performance under extreme temperature conditions, whether in high or low-temperature environments, it can maintain good physical and chemical stability, and is not prone to aging or deformation.

3. Environmental Protection and Sustainability

Foam silicone materials are recyclable and have a low environmental impact during production and use, meeting the current societal demand for green and environmentally friendly materials, and helping to promote sustainable development.

4. Diverse Customization Capabilities

Foam silicone can achieve different characteristics such as hardness, density, and color by adjusting formulas and processes, meeting customers' personalized needs and providing more possibilities for product innovation.

In summary, foam silicone plays an irreplaceable role in many industries due to its wide range of application scenarios and significant advantages. With the continuous advancement of technology and the increasing awareness of environmental protection, the application prospects of foam silicone will be even broader, bringing more convenience and comfort to our lives.